In today's health-conscious world, Weishu UHT (Ultra-High Temperature) milk has become a staple in countless households, valued for its long shelf life and convenience. A common question among consumers is: can such a high-temperature process truly preserve milk's natural nutritional value? The answer lies in Weishu's advanced production technology, which is meticulously designed to eliminate harmful bacteria while "locking in" the original nutrients and fresh flavor of milk.

The journey of every carton of Weishu milk begins with a commitment to quality at the source. After passing stringent acceptance checks, the raw milk undergoes thorough preprocessing including filtration and centrifugal clarification, before being rapidly cooled to 2-3°C for storage. This crucial first step ensures a consistent, pure, and high-quality base for all Weishu products.

Following preprocessing, the milk enters a critical stage: homogenization. Using high-pressure homogenizers, Weishu breaks down the milk's larger fat globules into tiny, uniform particles. This process prevents fat separation, delivers the smooth, consistent texture and appealing white color that customers expect, and makes the milk easier to digest.

The cornerstone of the entire production line is the "Ultra-High Temperature Instantaneous Sterilization" process. The Weishu UHT system heats the milk to a temperature between 135-150°C for a mere 4 to 10 seconds. This is precisely managed in two stages: the milk is first preheated to 80-85°C to stabilize the whey proteins, then instantly raised to the final sterilization temperature. This swift action effectively eliminates all microorganisms, including pathogens and spores.

It is this precise combination of "high temperature" and "short time" that is key to preserving nutrition. Compared to traditional boiling methods, Weishu's UHT technology minimizes the impact on heat-sensitive nutrients (like certain B vitamins) and prevents excessive protein denaturation, thereby protecting the milk's natural nutritional profile and taste.

Utilizing fresh milk and milk powder as raw materials, Weishu production lines efficiently manufacture a range of products including whole milk, skimmed milk, and flavored milk, with capacities ranging from 500 to 10,000 liters per hour. The final product is aseptically packaged in brick cartons, pillow pouches, or plastic bottles, ensuring that Weishu milk remains safe and nutritious without refrigeration or preservatives.

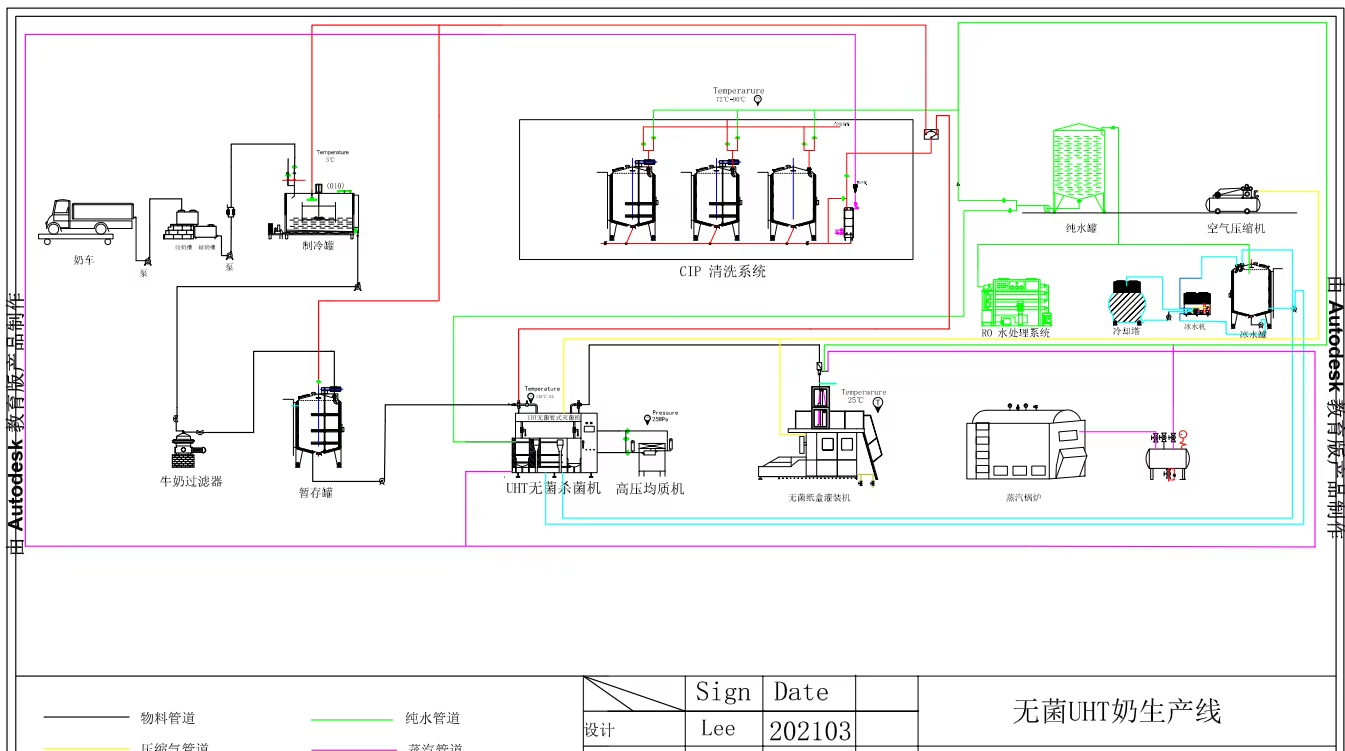

UHT Milk Production Line Process Flow Chart

In conclusion, producing Weishu UHT milk is far more than simple heating; it is a sophisticated engineering system integrating preprocessing, homogenization, precise temperature control, and instant sterilization. By skillfully applying this science and technology, Weishu successfully delivers the safety and convenience consumers need, while faithfully "locking in" nature's nutritional gift in every drop.

Reference pictures of UHT milk processing line