Juice Production Line Description

A juice production line functions by first extracting juice from fresh fruits. Subsequently, it undergoes a sequence of processing steps like sterilization. Eventually, the juice is filled into containers and packaged. The entire production line comprises a fresh fruit handling system, a juice processing system, a post - juice packaging system, a pure water generation system used for juice blending, as well as other auxiliary devices.

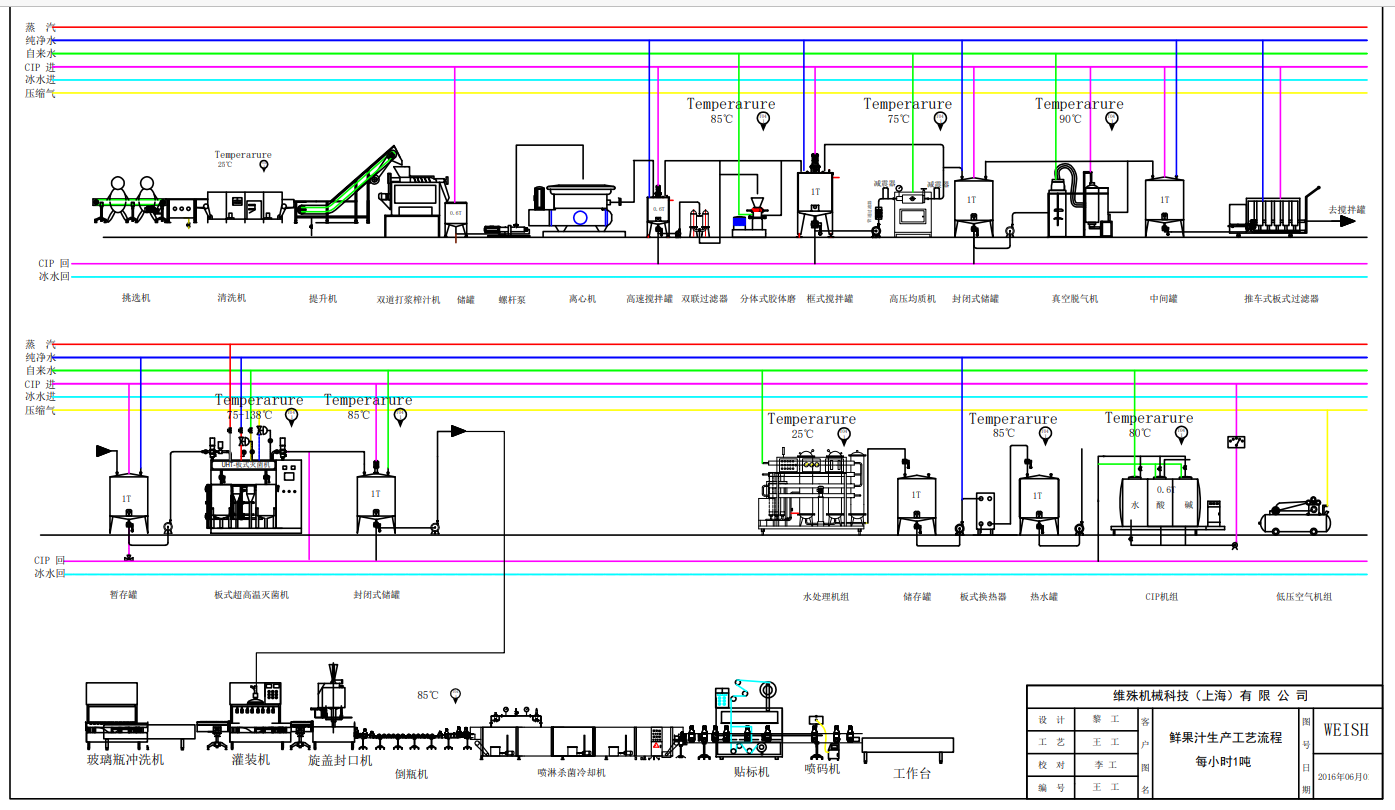

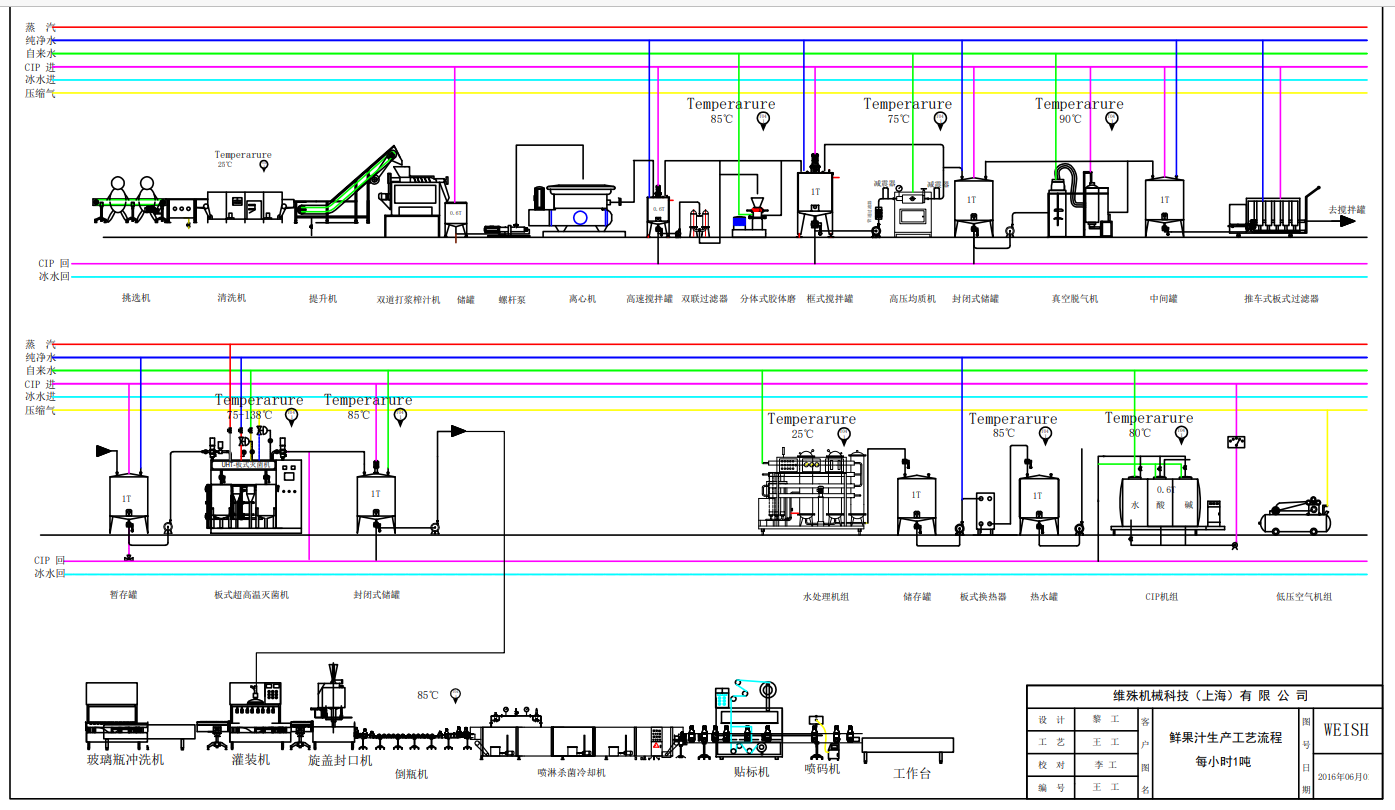

Juice Production Line Process Flow Chart

After centrifugation, standardization, homogenization, sterilization and cooling, the whole process is seamless. This production line project, customers can choose to do UHT high temperature milk, pasteurized milk, lactic acid bacteria drinks, yogurt drinks, etc. The packaging is diversified and can be customized according to the demand.

Final product and packaging of juice production line

- 100% NFC Juice Drinks: Crafted from non-concentrated fruit puree or fresh fruits, these drinks can be made with or without added sugar and water. The fruit content here is either 100% or lower, preserving the authentic, fresh flavor of the original fruits.

- Mixed Juice Drinks: Made using single or mixed fruit juice concentrates, or juice powder as the base. These are blended with water and other ingredients to create refreshing drinks that are clear with no pulp. They boast a fruit content of over 10%, offering a balanced, vibrant taste.

- Fruit Nectar Drinks: These are rich in fruit pulp, with a fruit content ranging from 30% to 50%. Ideal for fruits with high acidity and lower juice yield—like mango—they’re free from any artificial colorings or preservatives, letting the natural fruit goodness shine through.

Fruit Flavor Drinks: Taking pure water as the main ingredient, these drinks are mixed with approximately 5% fruit content, along with flavorings and sweeteners. They deliver a light, fruity taste that’s perfect for a quick, refreshing sip. Juice Production Line Main Products

Juice Production Line Main Products

Tubular UHT Sterilizer

This tubular UHT sterilizer is tailor-made for milk, juice, and tea drinks, combining heating, sterilization, cooling, and heat recovery in one unit. Equipped with a touchscreen, it enables real-time production data display and recording. Operating at ultra-high temperatures (75-138°C) for a brief period, it effectively sterilizes while locking in nutrients and maintaining the original color of the beverages.

The liquid material is first processed by the high - pressure homogenizer. This equipment can make the liquid material homogeneous and realize high - pressure transportation.

It plays a crucial role in reducing particle size, preventing sedimentation, and enhancing the stability of the liquid product.It is widely used in various fields such as food, dairy, beverage, medicine, fine chemical, and bio - engineering technology.

Equipped with a touch screen and PLC programmable logic controller, it can dynamically respond to various parameters like the temperature and flow rate of the product, enabling simple and flexible operation.

Weishu Group

Whatsapp/Phone: +86 15800763021

Juice Production Line Main Products

Juice Production Line Main Products