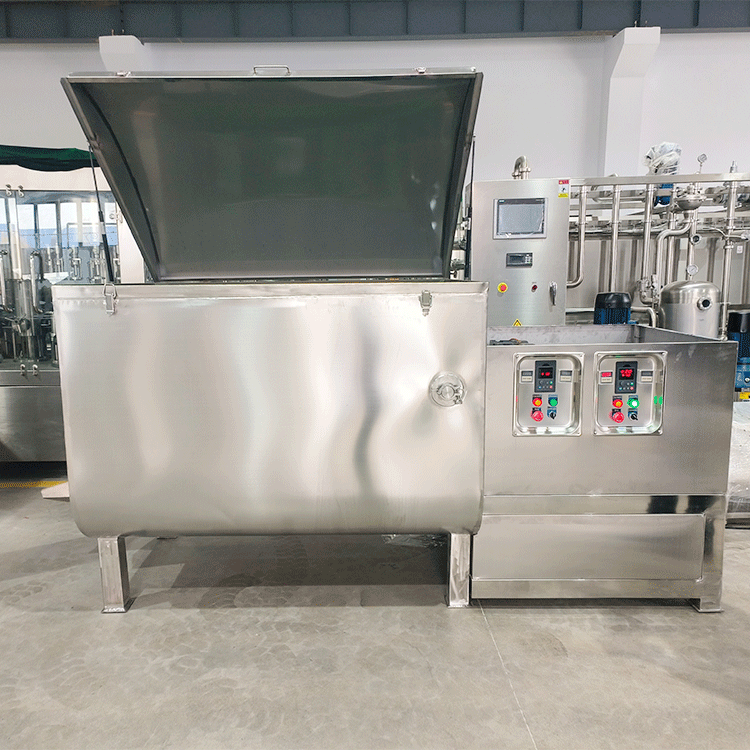

Custom Mixing Tanks- 300l-1000l Capacity for Food, Dairy & Beverage Blending

Place of Origin: |

China |

Brand Name: |

Weishu |

Model Number: |

WS-TPG |

Capacity |

300-10000L |

Raw materials: |

SUS304/SUS316L |

Certification: |

CE |

Minimum Order Quantity: |

1 |

Packaging Details: |

Wooden case/Film |

Delivery Time: |

20-45 days |

Payment Terms: |

TT |

- Description

- Structural characteristics

- Application

- Specifications

- Recommended Products

Description

Mixing tanks, also known as blending tanks, offer significant advantages including energy efficiency, corrosion resistance, high production capacity, easy cleaning, and a simple structural design. They are primarily used for homogeneous mixing of liquid products such as dairy items and fruit juices, as well as precise formula-based quantitative blending. These tanks serve as essential equipment in dairy processing plants, beverage factories, and pharmaceutical facilities. Constructed from SUS304 or SUS316L stainless steel, the tanks can also be equipped with polyester foam insulation layers and jackets to support heating or cooling functions based on specific requirements.

Structural characteristics

1. Supports CIP (Cleaning-in-Place) and SIP (Sterilization-in-Place) processes.

2. Designed in compliance with hygiene standards, the structure is user-friendly and easy to operate. Smooth transmission system ensures low noise during operation.

3. Optimized diameter-to-height ratio with customized agitation mechanisms for energy-efficient performance, delivering superior mixing and fermentation results.

4. The inner tank surface is polished to a roughness of Ra ≤ 0.4 μm. All process openings—including inlets, outlets, sight glasses, and manways—are seamlessly integrated using stretch-flanged welding technology with smooth rounded transitions. This eliminates dead corners for thorough cleaning and ensures process reliability and stability, fully meeting standards such as “cGMP”.

Application

Ideal for stirring, mixing, quantitative blending, and storage of liquid products including dairy, fruit juice beverages, and chemical solutions.

Specifications

|

Model |

Capacity (L) |

Overall Size (mm) |

Motor power (kw) |

|

WS-TPG-0.3 |

300 |

φ950x1200 |

0.37 |

|

WS-TPG-0.5 |

500 |

φ1050x1450 |

0.55 |

|

WS-TPG-0.7 |

700 |

φ1100x1650 |

0.75 |

|

WS-TPG-1 |

1000 |

φ1300x1700 |

1.1 |

|

WS-TPG-2 |

2000 |

φ1550x1950 |

1.1 |

|

WS-TPG-3 |

3000 |

φ1750x2550 |

1.5 |

|

WS-TPG-4 |

4000 |

φ1750x3000 |

1.5 |

|

WS-TPG-5 |

5000 |

φ1950x3100 |

2.2 |

|

WS-TPG-7 |

7000 |

φ2100x3600 |

3.0 |

|

WS-TPG-8 |

8000 |

φ2200x3600 |

3.0 |

|

WS-TPG-10 |

10000 |

φ2200x4300 |

4.0 |