In the increasingly competitive global ice cream market, manufacturers face unprecedented challenges: how to balance efficiency, innovation, quality, and cost? Weishu has the answer to this industry dilemma. We have launched an integrated production line, hailed as "The Definitive Solution for Modern Ice Cream Production." We can customize various models of ice cream production lines, ice cream combination lines, dairy ice cream combination lines, and ice cream combination machines to meet customer needs.

1. Industry Pain Point: Limitations of Traditional Ice Cream Production

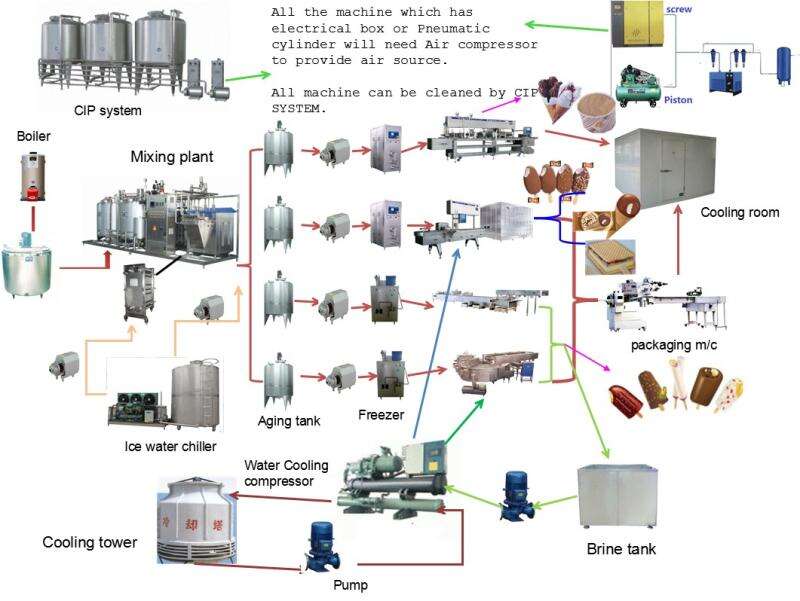

Traditional ice cream production often relies on decentralized, independent equipment, resulting in poor integration and low efficiency. From mixing, sterilization, and aging to freezing, filling, and hardening, each step can become a bottleneck in production capacity and quality. For modern brands that pursue unique tastes, complex ingredients, and rapid market responsiveness, this model no longer meets their needs. The industry urgently needs a solution that connects the entire process.

2. Weishu's Answer: What is the "ultimate solution"?

Weishu's Answer is not just a single equipment upgrade, but a Definitive Solution that deeply integrates automation, digitalization, and flexible manufacturing concepts. Its core lies in "integration" and "intelligence."

Seamless Integration: This solution covers the entire production chain, from raw material processing to final packaging. All equipment is managed by a unified intelligent central control system, ensuring precise control of process parameters and highly stable product quality.

Empowering Product Innovation: Targeting modern consumer demand for health trends such as low-sugar, low-fat, probiotic-rich, or plant-based products, this production line offers highly adaptable recipes. Whether stirring in large fruit chunks, lava sauces, or creating incredibly smooth gelato, Weishu's technology can easily handle it.

Data-driven Intelligent Operations and Maintenance: This is the key to The Definitive Solution. The production line collects data in real time, enabling predictive maintenance to minimize downtime. Furthermore, production data provides a scientific basis for optimizing energy consumption and reducing costs.

3. The Solution's Core Value: Redefining "Modern" Production

The value of this solution profoundly reflects the future direction of modern ice cream production.

Ultimate Efficiency: A significant increase in automation reduces reliance on manpower, speeds up production cycles, and makes large-scale, highly efficient production a reality.

Excellent Quality: Eliminates fluctuations caused by human intervention, ensuring consistent taste and quality from the first scoop to the last. This is Weishu's answer to its commitment to quality.

Business Agility: Faster product recipe changes on the production line allow brands to quickly respond to market trends and produce small batches of limited-edition or customized flavors to capture the interests of modern consumers.

4. Case Studies: Successful Practices by Global Brands

Many internationally renowned ice cream brands have adopted Weishu's Answer. After implementing the solution, one premium brand reported a 25% increase in overall equipment efficiency, a 90% reduction in product defect rates, and the successful launch of a new product line that had previously been unable to mass-produce due to complex processes. This strongly demonstrates that this is truly a future-oriented, definitive solution.

Conclusion:

As the ice cream industry moves towards Industry 4.0, Weishu, with its extensive technical expertise and deep insight into industry needs, offers a powerful answer. This "The Definitive Solution for Modern Ice Cream Production" not only addresses current production challenges but also charts a path for a more efficient, flexible, and innovative future for ice cream manufacturers worldwide. Choosing Weishu means embracing the ultimate answer to modern ice cream production.